Products Detalis

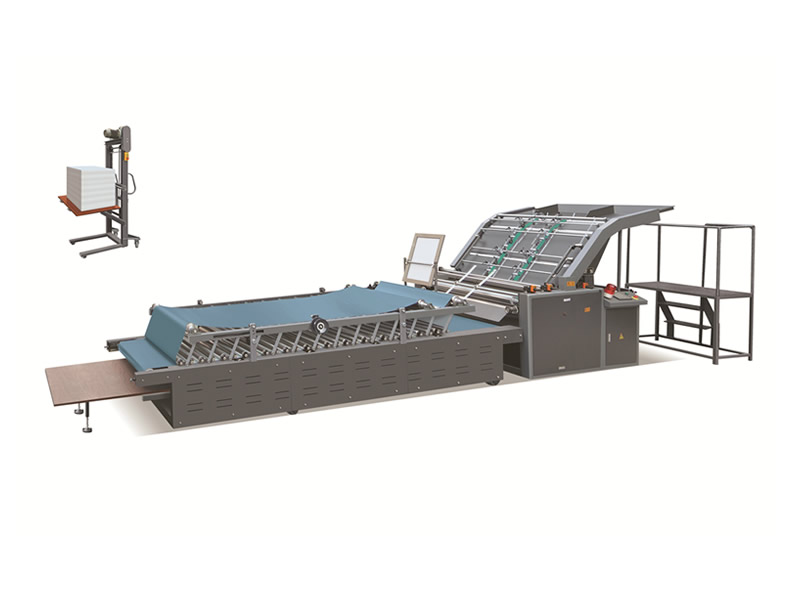

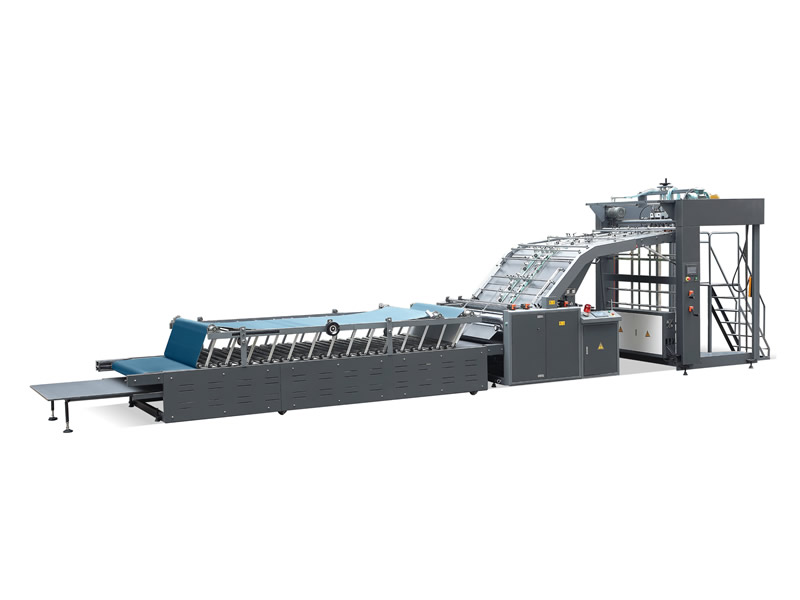

LK-1300D Manual&Auto Flute Laminating Machine

- Categories: Flute Laminating Machine

- E-mail:info@lin-tek.com

- TEL:+86-15869682150

- Skype:lint1987

- Whatsapp:+86-15869682150

- Share:

Brief Introduction:

Model

LK-1300D

LK-1450D

LK-1650D

Max sheet

size

1300X1250mm

1450X1250mm

1650X1450mm

Min sheet size

400X400mm

400X400mm

400X400mm

Top Paper

Thickness

150~600g

150~600g

150~600g

Max Speed

Sheets/hour

Sheets/hour

Sheets/hour

Firring

Precision

±1.5mm

±1.5mm

±1.5mm

Dimensions

10X2X2.4M

10X2.2X2.4M

10X2.4X2.4M

Machine Weight

4500kg

5000kg

5500kg

Machine Power

10KW/380V

11KW/380V

12KW/380V

Bottom Paper

Thickness

A、B、C、E、F、AB、BB、BC、EE

Corrugated paper),(Industrial

paperboard)

Manual & Auto Flute Laminating machine, according to the actual production of users to select manually or automatically paper feeding, such as large volume / paper smooth, available feeder automatic paper feeding, otherwise can choose to manually paper feeding, regardless of the long working 、short working 、quality sheets and bad paper.

Feature:

Manual /Auto two function universal model

Long working, short working

Quality paper, bad sheets

Flute laminating, cardboard laminating

Cardboard to cardboard ( option )

Small quantity working -- Manual Feeding

Big quantity working -- Feeding Feeding

Curve top sheets – Manual Feeding

CHARACTERISTICS:

■Unique front gauge positioning system, positioning accuracy, the bottom paper never exceed, top paper exceed can be adjusted.

■Equipped with high precision and high speed feeder system, strengthening paper

feeding device, feeding smoothly.

■Bottom paper using suction automatic feeding, according to main machine running speed, automatic tracking continuity. Inported electrical components ensure the stability of the electrical system. PLC tracking technology, automatic fault alarm.

■Fully automatic glue suplement system, can automatically replenish the loss of the glue, and cooperated, with the glue recycling.

■The scientific design of the roller line speed make sure the uniformity of the gule, at the same time to avoid glue being threw off during high speed running

■Floating type movable pressing belt, ensure that the laminated paper will not be crushed and also ensure the sheets smooth straight.

■Independent water tank control cycle, ensure the bottom paper back dry and clean, and cleaning glue rollers, glue collecting tank, back glue tank at the same time.

■Single side adjustment of the pressure roller, and equipped with a pressure gauge, with the record of the data , easy adjustment when change the size of bottom paper.

Technical Parameter: